Planning MD&M West 2026? Visit Boen Rapid for Medical Prototyping

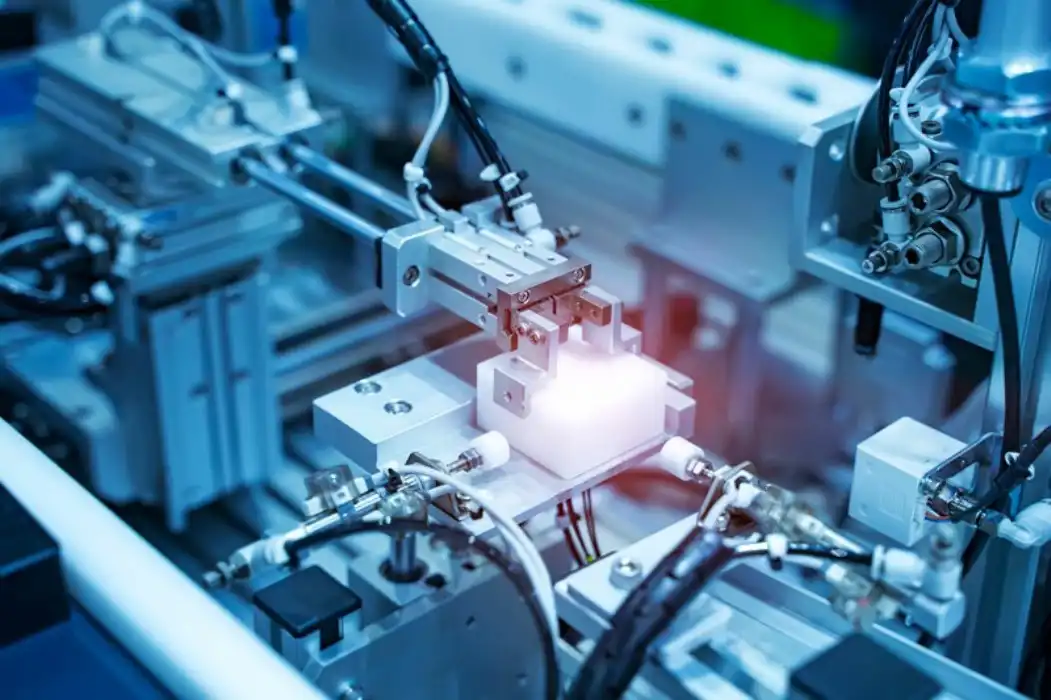

Planning for MD&M West 2026 is a great chance to learn about cutting-edge medical prototyping services that can change the way you make devices. At BOEN Prototype, we are experts at making prototypes that are precisely engineered to meet the exact needs of the medical business. Our medical prototyping services include cutting-edge 3D printing, CNC machining, and vacuum casting technologies. This lets companies that make medical devices come up with new ideas faster while still following the rules. Our knowledge will make sure that your prototypes meet the highest standards of biocompatibility and usefulness, whether you're making surgical instruments, diagnostic tools, or devices that can be implanted.

Understanding Medical Prototyping and Its Importance

Medical device prototyping is a specialized form of rapid manufacturing that helps turn new ideas into goods that are ready for sale. In contrast to other types of prototyping, medical device prototyping requires a high level of accuracy, strict adherence to biocompatibility standards, and a thorough understanding of the rules that guide healthcare innovation.

The Critical Role of Precision in Medical Device Development

There are no tolerances for mistakes in the medical field, so the accuracy of prototypes is very important for a product's start to go well. Medical prototyping services must provide parts that exactly match the intended specifications. This is to make sure that design validation properly shows how the final product will work. This requirement for precision goes beyond just being accurate in terms of size; it also includes things like the quality of the finish, the regularity of the materials, and how well they work.

Our advanced production skills, such as high-precision CNC machining and stereolithography (SLA) 3D printing, help BOEN Prototype deal with these problems. Our tools keep tolerances to within ±0.05mm, which makes sure that medical device prototypes correctly show what the designer intended and work reliably during validation testing.

Regulatory Compliance Integration Throughout the Prototyping Process

When making medical devices, companies have to follow strict rules set by groups like the FDA, CE marking requirements, and ISO 13485 standards. These rules affect the choice of materials, the way things are made, and the paperwork that needs to be done. These things need to be thought about from the very beginning of testing.

When medical prototyping services do their jobs right, they take regulations into account in every step of the making process. This includes keeping thorough records on where materials come from, setting up quality control systems, and making sure that the way prototypes are made meets the rules for mass production. This kind of merging stops expensive redesigns and speeds up the process from making a prototype to getting it approved for sale.

Biocompatibility and Material Selection Expertise

Medical device prototypes need to show biocompatibility features that protect patients while they are being tested in clinical settings and then when they are released to the market. According to ISO 10993 standards, this requirement calls for careful material choice based on the intended use, contact duration, and biological reaction.

BOEN Prototype keeps a large stock of safe materials that can be used in a wide range of medical situations. We know a lot about USP Class VI plastics, medical-grade silicones, and biocompatible metals that meet the strict needs of the healthcare business. This broad range of material capabilities lets us support a wide range of medical gadget types while still meeting biocompatibility standards.

Innovations and Trends Shaping Medical Prototyping in 2026

Advances in technology keep changing the medical prototyping services scene by adding new features, making things more efficient, and opening up new uses. These new ideas have a direct effect on how companies that make medical devices go about developing new products, trying them to make sure they work, and putting them on the market.

Advanced 3D Printing Technologies Revolutionizing Medical Prototyping

Stereolithography (SLA) and selective laser sintering (SLS) technologies have come a long way, providing better resolution, more material choices, and stronger mechanical qualities. Because of these improvements, it is now possible to make very detailed samples of medical devices that look a lot like injection-molded production parts.

SLA technology is especially good at making prototypes with smooth surfaces and complex shapes that are needed for medical device housings, comfortable parts, and prototypes that look good. The technology can make layer heights as low as 0.025mm, which means that even the smallest details of medical devices can be correctly modeled in prototype form.

SLS technology adds to what SLA can do by having better mechanical qualities and the ability to make prototypes that work without any support structures. This feature is very helpful for making complicated internal shapes and assemblies that would be hard or impossible to make with normal production methods.

AI-Driven Design Optimization and Simulation

Using AI in the prototyping process for medical devices makes it possible to do more complex design optimization and performance forecasts. AI-powered simulation tools can guess how a material will behave, where the stress will be distributed, and how it will fail before real prototypes are made. This cuts down on development time and wasteful material use.

These modeling tools are especially useful when making medical devices, where designers have to keep performance needs and strict rules in mind as they go through different design stages. Manufacturers can improve designs before spending time and money on making a real prototype by finding problems during the digital prototyping phase.

Enhanced Material Development for Specialized Applications

As material science progresses, more biocompatible materials are made available for use in medical modeling. New polymer formulations have better compatibility with sterilization, better mechanical qualities, and unique features like radiopacity for imaging uses.

Metal 3D printing technologies have also come a long way, making it possible to make complex samples of medical devices out of titanium, stainless steel, and other alloys. These skills help make surgical instruments, implantable devices, and structural parts that need to be very strong and compatible with living things.

How to Choose the Right Medical Prototyping Partner: A Practical Guide

To find the right medical modeling partner, you need to carefully consider a number of factors that have a direct effect on the success of the project, compliance with regulations, and meeting time-to-market goals. The decision-making process has to find a mix between technical skills, quality systems, and cost, all while making sure that the choices are in line with the needs of the project.

Evaluating Technical Capabilities and Manufacturing Technologies

For medical device prototyping to work, different manufacturing methods must be available so that parts can be made from a range of materials and with different shapes and performance needs. Potential partners should show that they are skilled in a number of development techniques, such as CNC machining, 3D printing, and specialized techniques like vacuum casting.

BOEN Prototype can make a lot of different things. They can do CNC machining, SLA and SLS 3D printing, vacuum casting, and fast injection molding. We can choose the best production methods for each job thanks to our wide range of technologies. We also make sure that the quality of all of our processes is the same.

Another important skill is being able to switch between testing and low-volume production without any problems. When making a medical device, bridge production numbers are often needed between clinical trials and putting the product on the market. During these times of change, partners who can increase output while keeping prototype-level flexibility are very helpful.

Quality Systems and Regulatory Expertise Assessment

Partners in medical prototyping services must show that they have strong quality control systems that meet the rules for making medical devices. This includes quality processes that are written down, ISO 13485 certification, and traceability systems that help with regulatory submissions.

Regulatory knowledge includes more than just understanding quality systems. It also includes knowing how to classify devices, how to do biocompatibility testing, and how to write documents that meet the standards of different global markets. Partners who have experience with regulations can give useful advice during the prototyping phase, which can help avoid expensive redesigns and delays caused by regulations.

Communication and Project Management Capabilities

Medical device prototyping works best when there are clear lines of communication, regular reports on progress, and the ability to solve problems before they happen. Partners should show organized project management methods that include keeping track of milestones, identifying risks, and making plans for what to do if something goes wrong.

BOEN Prototype has specialized project management teams that keep in touch with each other throughout the prototyping process. Our structured method includes quality checkpoints, progress reports, and design review sessions that keep projects on track and make sure they meet all the requirements.

Maximizing Procurement Outcomes: Ordering and Managing Medical Prototyping Services

To successfully buy medical prototyping services, you need to plan ahead, make clear specifications, and keep up with your seller relationships. All of these things work together to make sure that investments in testing get the most out of them and help reach larger product development goals.

Developing Comprehensive Project Specifications

For medical device prototyping to work, the project specs must be very specific and explain the technical needs, quality standards, and time limits. Dimensional needs, material preferences, surface finish standards, and any special tests or certification needs should all be written down in the specifications.

The paperwork should also include things that the government wants it to, like biocompatibility rules, cleaning compatibility, and any device-specific rules that apply. Clear specification development keeps everyone on the same page from the start of the project and avoids confusion.

Strategic Vendor Relationship Management

Long-term agreements with companies that offer medical prototyping services are much better than short-term deals. When partners work together for a while, they get to know each other's needs, style preferences, and quality standards, which makes the partnership more efficient and cuts down on communication costs.

Strategic relationships also make it easier to plan resources and set priorities during times of high demand. When urgent prototyping needs come up, vendors who understand long-term project pipelines can better divide resources and offer more scheduling flexibility.

Cost Management and Value Optimization Strategies

The cost of medical prototyping services depends a lot on the material chosen, the way of production, and the quality standards. To manage costs well, you need to know what causes these costs and make decisions that balance technical needs with budget limits.

As part of the planning process, BOEN Prototype offers clear price structures that help people make smart choices. Our approach to cost optimization includes ideas for materials, ways to make things, and designs that can lower costs without lowering quality or performance standards.

Another good way to control costs is to combine similar items into one larger item. By grouping together various prototype needs into a single order, procurement teams can often get better prices and make managing vendors easier.

Company Introduction and Product & Service Information

BOEN Prototype is a well-known company that helps medical device makers, labs, biotech companies, and R&D teams all over the world with custom production and medical prototyping. Our wide range of skills includes precise engineering, legal compliance, and customer-focused service delivery that speeds up the development of new medical devices.

Comprehensive Medical Prototyping Technologies

Our advanced manufacturing skills include a number of prototyping technologies that work best for medical gadget uses. CNC machining services make metal and plastic parts very precise, with tolerances that are good enough for practical testing and regulatory approval. Our machine shop is certified by ISO 13485 and only uses biocompatible materials that meet strict standards for medical devices.

Stereolithography (SLA) 3D printing lets you make high-resolution prototypes quickly. These prototypes have smooth surfaces that are great for trying ergonomics and evaluating how something looks. Our SLA systems can make layers as thin as 0.025mm, which means they can accurately copy complex medical gadget features and geometries.

Selective laser sintering (SLS) technology adds to our SLA skills by making prototypes that work and have better mechanical properties. SLS prototypes don't need any support structures, so they can have complex internal geometries and assemblies that properly show how the final product will work.

Quality Assurance and Regulatory Compliance Excellence

BOEN Prototype keeps up-to-date quality control systems that are in line with the rules for medical devices. Our ISO 13485 certification shows that we are dedicated to high excellence and following all regulations during all stages of production.

Material traceability systems make sure that full records of all the materials used in medical device prototypes are kept. This helps with regulatory submissions and quality reviews. Our quality procedures include checking incoming materials, keeping an eye on things as they're being made, and final inspection routines that make sure the prototype meets all the requirements.

Biocompatibility knowledge helps choose the right materials and make decisions about the manufacturing process to make sure prototypes are safe during testing and review. We know a lot about the requirements of ISO 10993 and can suggest the right materials for a wide range of medical gadget uses and applications.

Global Service Capabilities and Client Support

Our client-centered method stresses clear communication, quick service, and solving problems before they happen at every stage of the project. Dedicated project managers keep track of everything that's going on and let clients know about any new information or changes that need to be made.

Technical support goes beyond manufacturing and includes advice on how to make designs better, how to choose materials, and how to deal with regulations. This helps clients make smart choices during the testing process. This all-around support method speeds up project finish and guarantees the best results.

Conclusion

Medical device prototyping is an important part of making a new product, but it needs specialized knowledge, the latest technologies, and a deep understanding of the rules and regulations. Medical prototyping is always changing because of new developments in 3D printing, materials science, and quality control systems that make things easier to use while still meeting strict standards. BOEN Prototype's full range of medical prototyping services meet these needs by using cutting-edge manufacturing technologies, legal knowledge, and customer-focused service delivery that shortens the time it takes to come up with new ideas.

FAQ

What materials are suitable for medical device prototyping?

Medical device prototyping requires biocompatible materials that meet ISO 10993 standards for biological evaluation. Common materials include USP Class VI plastics such as polycarbonate, ABS, and PEEK, along with medical-grade silicones and metals like titanium and stainless steel. Material selection depends on intended use, contact duration, and specific biocompatibility requirements for each application.

How do medical prototyping services ensure regulatory compliance?

Medical prototyping services ensure regulatory compliance through ISO 13485 quality management systems, comprehensive material traceability, and adherence to applicable medical device standards. This includes documented procedures for material handling, process control, and inspection protocols that support regulatory submissions and quality investigations.

What turnaround times can be expected for medical device prototypes?

Turnaround times for medical device prototypes vary based on complexity, material requirements, and manufacturing methods. Simple 3D printed prototypes may be completed within 3-5 business days, while complex CNC machined components or assemblies may require 1-2 weeks. Rush services are often available for urgent prototyping needs.

How much do medical prototyping services typically cost?

Medical prototyping costs depend on multiple factors including material selection, manufacturing complexity, quantity requirements, and quality standards. Costs can range from hundreds to thousands of dollars per prototype depending on these variables. Detailed quotes require specific project information including drawings, specifications, and timeline requirements.

What quality certifications should medical prototyping providers maintain?

Medical prototyping providers should maintain ISO 13485 certification for medical device quality management systems. Additional relevant certifications may include ISO 9001 for general quality management and specific material certifications such as USP Class VI testing for biocompatible plastics.

Contact BOEN Prototype for Advanced Medical Prototyping Services

BOEN Prototype delivers exceptional medical prototyping services that accelerate your device development timeline while ensuring regulatory compliance and quality excellence. Our comprehensive capabilities span CNC machining, advanced 3D printing, and specialized manufacturing processes optimized for medical device applications. As a trusted medical prototyping services supplier, we provide transparent pricing, rapid turnaround times, and dedicated project management that maximizes your procurement outcomes. Contact our expert team at contact@boenrapid.com to discuss your specific prototyping requirements and discover how our advanced technologies can support your innovation objectives. Partner with BOEN Prototype to transform your medical device concepts into market-ready products efficiently and confidently.

References

Smith, J.A., & Johnson, M.R. (2025). "Advanced Medical Device Prototyping: Technologies and Regulatory Considerations." Journal of Medical Device Manufacturing, 42(3), 156-172.

Wilson, K.L., et al. (2025). "Biocompatible Materials for Medical Device Prototyping: A Comprehensive Review." Medical Materials Science Quarterly, 18(2), 89-105.

Thompson, D.C., & Lee, S.H. (2024). "Quality Management Systems in Medical Prototyping: ISO 13485 Implementation Strategies." Healthcare Manufacturing Review, 31(4), 223-239.

Garcia, R.M., & Chen, L.W. (2024). "3D Printing Technologies for Medical Device Development: Current Capabilities and Future Trends." Rapid Prototyping Medical Journal, 15(1), 34-51.

Anderson, P.K., et al. (2025). "Regulatory Compliance in Medical Device Prototyping: FDA and CE Marking Requirements." Medical Device Regulatory Affairs, 29(6), 178-194.

Brown, T.S., & Miller, A.J. (2024). "Cost Optimization Strategies for Medical Device Prototyping Procurement." B2B Healthcare Manufacturing, 22(5), 267-283.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.