Can CNC Machining Produce High-Quality ABS Housings

Without a doubt, CNC machining services are capable of producing ABS housings of superior quality that fulfill stringent industrial requirements. The use of sophisticated computer-controlled manufacturing methods allows CNC machines to precisely shape solid ABS blocks into housings with outstanding surface finishes, dimensions, and precision. Precision and repeatability are key in many industries, including aerospace, automotive, electronics, and medicine, and CNC machining's automated process guarantees both. The combination of ABS material's durability and adaptability with CNC technology's accuracy makes this manufacturing strategy perfect for prototype and low-volume production.

Understanding CNC Machining and Its Role in ABS Housing Production

Computer Numerical Control machining represents a sophisticated manufacturing approach that transforms raw ABS material into precisely engineered housings through automated subtractive processes. The technology operates using pre-programmed software commands called G-code and M-code, which direct cutting tools to remove material with exceptional accuracy and consistency.

The Fundamentals of CNC Technology

CNC machines function as computerized manufacturing systems that eliminate human error while maintaining superior precision throughout the production cycle. These advanced systems utilize end mills controlled by sophisticated software that references 3D CAD models to reduce stock material into desired geometries. The automated nature of this process enables manufacturers to achieve tolerances as tight as ±0.005 inches consistently across multiple production runs.

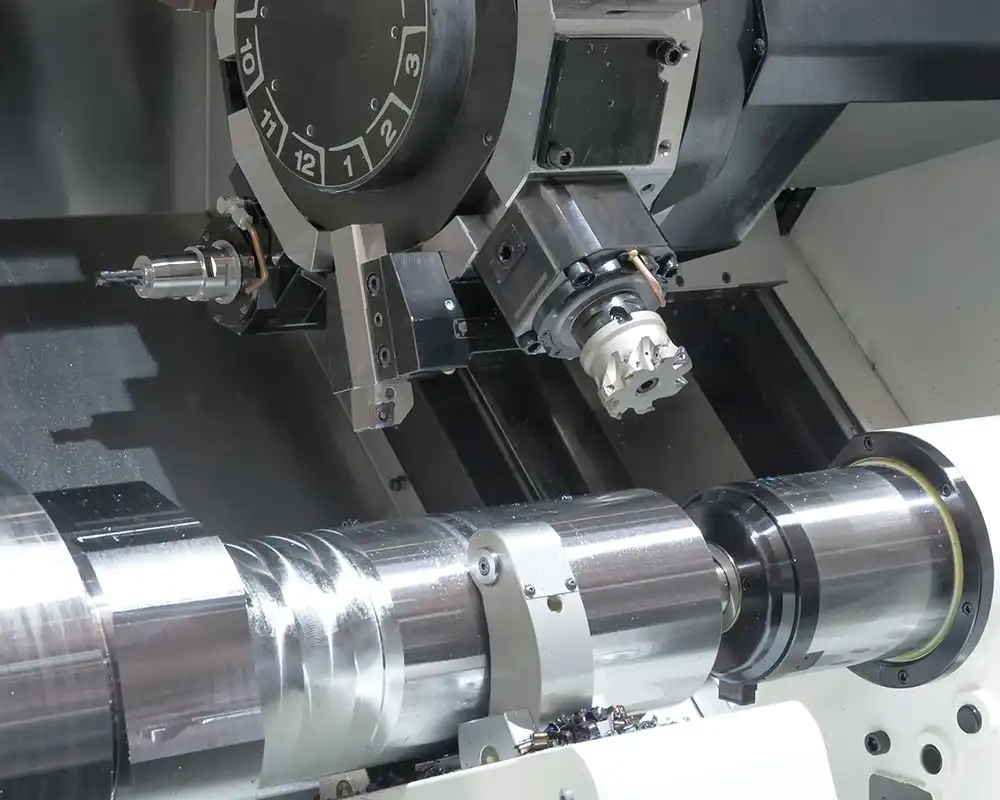

Modern CNC equipment includes various machine types such as milling centers, turning lathes, and multi-axis systems that can handle complex geometries common in housing applications. The versatility of these machines allows for intricate features like threaded holes, undercuts, and complex internal cavities that traditional manufacturing methods struggle to achieve efficiently.

ABS Material Properties for CNC Applications

Precision CNC operations are a perfect fit for Acrylonitrile Butadiene Styrene due to its outstanding machinability properties. During machining processes, the material shows remarkable dimensional stability, which minimizes the chances of distortion or warping that might lower the quality of the finished object. ABS's constant cutting qualities allow for repeatable surface finishes and predictable tool wear patterns even after extensive machining.

Because of its thermoplastic composition, ABS is able to withstand CNC machining services operations without experiencing the brittleness that may occur with other plastics. Automotive electronics, consumer electronics, and medical equipment are just a few of the many sectors that find ABS to be an ideal housing material due to its chemical stability, impact resistance, and balanced mix of the three.

Precision Advantages Over Manual Methods

CNC machining delivers measurable advantages compared to conventional manual machining approaches. Automated tool positioning eliminates operator variability while ensuring consistent part-to-part quality throughout production runs. The technology enables complex multi-axis operations that would be impossible or extremely time-consuming to achieve manually.

Statistical process control capabilities inherent in CNC systems provide real-time monitoring of critical dimensions and surface quality parameters. This continuous feedback allows for immediate adjustments to maintain optimal cutting conditions and prevent defective parts from entering the production stream.

Key Benefits and Challenges of CNC Machining for High-Quality ABS Housings

The implementation of CNC technology for ABS housing production delivers compelling advantages while requiring careful consideration of specific challenges related to thermoplastic machining. Understanding both aspects enables procurement professionals to make informed decisions regarding manufacturing strategies.

Superior Precision and Scalability Benefits

When it comes to housing applications, CNC machining reliably meets or surpasses industry requirements for dimensional precision. While producing outstanding surface finishes that often do away with additional procedures, the technique consistently maintains tolerances inside ±0.002 inches across crucial dimensions. For tasks that need a tight fit and assembly with matching parts, this precision capability is essential.

When going from making a small number of prototypes to making a medium number of them, CNC machining's scalability benefits become obvious. Regardless of the amount of output, CNC systems retain constant quality, in contrast to manual processes which degrade with rising volume. Due to this uniformity, there is no need to rethink production methods in order to go from prototype to commercial production after market validation.

Shorter production times are a direct outcome of the increased efficiency brought about by CNC automation as opposed to more conventional methods of manufacturing. Modern machinery can run nonstop with no human oversight, allowing for 24-hour manufacturing cycles that shorten turnaround times without sacrificing quality.

Thermal Management Challenges

To avoid material deterioration and dimensional instability, ABS machining requires meticulous temperature control during cutting processes. Part integrity and surface quality might be compromised due to localized melting or stress concentrations caused by excessive heat production. Minimizing heat production is crucial for successful ABS machining, which involves optimizing cutting parameters such as spindle speed, feed rates, and tool shape.

In CNC machining services, achieving and sustaining ideal cutting temperatures becomes dependent on the correct use of coolant and evacuation of chips. The machining cycle may be successfully managed by modern CNC systems using complex cooling techniques such as mist systems, compressed air distribution, flood cooling, and other similar technologies.

Surface Finishing Considerations

It takes thermoplastic-specific tooling and cutting techniques to achieve perfect surface finishes on CNC-machined ABS housings. The combination of precise tool geometry, sharp cutting edges, and end-use-appropriate smooth surface texturing eliminates material smearing. When needed, surfaces with characteristics similar to a mirror may be achieved using advanced finishing processes like as diamond turning and fly cutting.

The results of surface quality are greatly affected by the tools that are used. When cutting plastics, specialist carbide tools with coatings and shape suited for the job operate better than regular metalworking tools. Consistent surface quality is achieved throughout production runs by following proper tool maintenance and replacement schedules.

Comparing CNC Machining with Alternative Manufacturing Methods for ABS Housings

B2B procurement professionals benefit from understanding how CNC machining compares with alternative manufacturing approaches to make optimal technology selections based on project requirements, quality expectations, and delivery timelines.

CNC Machining vs. 3D Printing Technologies

While FDM and SLA are additive manufacturing technologies, they can't match the precision and accuracy of CNC machining when it comes to surface finish and dimensions. This makes them less than ideal for fast prototyping. The mechanical qualities and surface quality of CNC machined components are better suited for end-use applications, but 3D printing is great at creating complicated interior geometries and minimizing material waste.

Extensive post-processing may be necessary to eliminate apparent layer lines and mechanical property changes caused by 3D printing build orientation restrictions. By providing isotropic mechanical qualities all across the component structure, computer numerically controlled machining removes these orientation dependencies.

While 3D printing has a distinct advantage when comparing lead times for individual prototypes, CNC machining starts to make a serious run for it when the quantity goes above 10 or 20 units. Compared to additive manufacturing's per-part expenses, CNC setup costs are better distributed over larger numbers.

CNC Machining vs. Injection Molding

While injection molding is the way to go for high-scale manufacturing, it may be rather costly to invest in tooling up front, which might not be worth it for low to medium volume needs. When tooling prices become too high for quantities between 50 and 5,000 pieces, CNC machining is a great technique to bridge the gap.

Rapid design iterations without tooling alterations are made possible by the design flexibility benefits of CNC machining services. Programming updates allow for fast implementation of engineering improvements, as opposed to the costly tool alterations needed in injection molding techniques.

With CNC machining, you may experiment with different ABS grades and formulas without having to commit to the huge volumes of material needed for injection molding. This capacity is very useful when optimizing materials is still an ongoing process throughout product development.

Local vs. Global Manufacturing Considerations

Domestic CNC machining services offer advantages in communication efficiency, quality oversight, and intellectual property protection that may outweigh potential cost savings from overseas manufacturing. Local suppliers enable face-to-face collaboration during development phases while providing faster response times for engineering changes and quality issues.

Quality assurance becomes more manageable with local suppliers through direct facility visits and real-time communication during production. Time zone alignment facilitates immediate problem resolution and reduces project delays associated with communication lag times common in international supply chains.

How to Procure High-Quality CNC Machining Services for ABS Housings

Successful procurement of precision CNC machining requires systematic evaluation of potential suppliers combined with clear communication of technical requirements and quality expectations. Professional procurement practices ensure optimal outcomes while building long-term supplier relationships.

Essential Supplier Evaluation Criteria

Quality certificates reveal a lot about the competence and maturity of the provider. Certification in areas such as AS9100 for aerospace and ISO 13485 for medical devices show competence, while ISO 9001 stands for well-established quality management systems. These accreditations attest to the company's dedication to quality and continuous process improvement, which in turn produces consistent products.

A supplier's ability to fulfill present and future demands is indicated by their equipment capabilities and levels of technological investment. When compared to earlier equipment, modern CNC centers produce better quality and use less energy because to their sophisticated control systems, automated tool changeover, and in-process monitoring capabilities. Investing in technological updates shows that suppliers are committed to the long-term and want to stay competitive.

Supplier performance in comparable applications and sectors may be better understood with the help of client testimonials and case studies. Client references that have similar quality standards and production quantities might give you an idea of what to anticipate in terms of delivery performance and quality consistency.

Pricing Models and Lead Time Optimization

CNC machining pricing typically reflects setup costs, machining time, material costs, and tooling requirements. Understanding these cost components enables more effective negotiations and helps identify opportunities for cost optimization through design modifications or volume adjustments. Setup costs can be amortized across larger quantities to reduce per-unit pricing.

Lead time factors for CNC machining services include programming time, setup requirements, machining duration, and quality inspection processes. Rush orders for CNC machining services may be accommodated but typically incur premium pricing that should be factored into project budgets. Advance planning and flexible delivery schedules for CNC machining services often enable better pricing and resource allocation.

Material sourcing strategies can significantly impact both cost and delivery performance. Suppliers with established material inventory or preferred vendor relationships may offer advantages in material cost and availability compared to those requiring special material orders for each project.

Technical Specification Communication

Detailed technical drawings with complete dimensional information, tolerance specifications, and surface finish requirements eliminate ambiguity and prevent costly misunderstandings. CAD file formats compatible with supplier systems facilitate accurate programming and reduce setup time. Clear material specifications including grade, color, and any special properties ensure proper material selection.

Quality inspection requirements should be clearly defined including critical dimensions, measurement methods, and documentation needs. First article inspection reports provide comprehensive verification of supplier capability while establishing baseline quality standards for subsequent production runs.

Case Study: Successful Production of High-Quality ABS Housings via CNC Machining

A consumer electronics manufacturer required precision ABS housings for a new smart home device that demanded tight tolerances and exceptional surface quality while meeting aggressive development timelines. The project demonstrated the effectiveness of CNC machining in delivering complex housing solutions under challenging requirements.

Project Requirements and Challenges

The housing design featured complex internal geometries with thin wall sections, precise mounting bosses, and integrated snap-fit features requiring tolerances within ±0.003 inches. Traditional manufacturing approaches proved inadequate for achieving the required precision while meeting the compressed development schedule. Surface quality requirements included Class A finishes on visible surfaces with minimal post-processing requirements.

Material selection focused on ABS due to its excellent balance of mechanical properties, dimensional stability, and finishing characteristics. The application required flame-retardant properties and specific color matching that limited material options to specialized ABS grades with higher material costs but superior performance characteristics.

Manufacturing Process Implementation

CNC programming utilized advanced CAM software to optimize tool paths and minimize cycle time while maintaining quality requirements. Multi-axis CNC machining services capabilities enabled complete part processing in single setups, eliminating secondary operations and improving dimensional consistency. Specialized tooling designed for plastics machining delivered optimal surface finishes while maximizing tool life.

Thermal management strategies included optimized cutting parameters, strategic cooling application, and careful chip evacuation to prevent heat buildup during thin wall machining operations. In-process measurement verified critical dimensions throughout the machining cycle, enabling immediate corrections when necessary.

Results and Lessons Learned

The CNC machining approach delivered parts meeting all dimensional and surface quality requirements within the specified timeline. Production yields exceeded 98% with minimal rework required, demonstrating the reliability of properly implemented CNC processes for precision ABS components. Total project timeline from design freeze to first production parts measured six weeks compared to estimated 12-week timelines for alternative manufacturing approaches.

Cost analysis revealed per-unit costs competitive with injection molding when tooling amortization was included, while providing significantly greater design flexibility and faster market entry. The success of this project established CNC machining as the preferred manufacturing approach for subsequent low to medium volume housing applications.

Company Introduction and Our CNC Machining Solutions for ABS Housings

BOEN Prototype specializes in delivering precision CNC machined ABS housings that meet the exacting requirements of diverse industries including automotive, electronics, medical devices, and aerospace applications. Our comprehensive manufacturing capabilities combine advanced CNC technology with deep material expertise to deliver exceptional results for both prototype and low-volume production requirements.

Advanced Manufacturing Capabilities

Our facility features state-of-the-art CNC machining centers equipped with advanced control systems and precision tooling specifically optimized for thermoplastic materials. Multi-axis capabilities enable complex geometries while maintaining exceptional dimensional accuracy and surface quality. Advanced workholding systems and custom fixtures ensure consistent part quality throughout production runs.

Quality management systems including ISO 9001 certification demonstrate our commitment to process excellence and continuous improvement for our CNC machining services. Comprehensive inspection capabilities including CMM measurement and advanced surface profiling ensure all parts meet specified requirements before delivery. Statistical process control monitors critical parameters throughout production to maintain consistent quality outcomes.

Customized Service Offerings

When it comes to service choices, BOEN Prototype has you covered from one prototype unit all the way up to production numbers in the thousands. While keeping aesthetic goals and practical needs in mind, our engineering team works directly with customers to optimize designs for CNC manufacture. Reviews of the design for manufacturability find ways to enhance quality and save costs before production starts.

We have extensive knowledge of a wide range of ABS grades and custom formulations, including flame-retardant, UV-stable, and food-grade varieties, so we can satisfy the needs of any unique application. Having strong ties with suppliers allows us to get materials at cheap prices without sacrificing quality. Based on the needs of the application and the desired level of performance, our staff may help with material selection.

By using rapid prototyping capabilities, development durations may be reduced while still allowing for speedy design validation and functional testing. In order to meet the pressing needs of your project without sacrificing quality, we provide expedited processing solutions. Schedule flexibility and prompt communication are two components of our dedication to client satisfaction that we provide throughout a project's lifespan.

Conclusion

CNC machining services demonstrates exceptional capability for producing high-quality ABS housings that meet demanding industry specifications across diverse applications. The technology delivers superior precision, consistent repeatability, and excellent surface quality while providing design flexibility unavailable in traditional manufacturing approaches. Understanding the benefits and challenges of CNC machining enables procurement professionals to make informed decisions that optimize quality outcomes while managing project timelines and budgets effectively. The strategic implementation of CNC manufacturing processes provides competitive advantages through reduced development cycles and enhanced product quality that supports successful market positioning.

FAQ

1. Can CNC machining achieve tight tolerances on complex ABS housing geometries?

CNC machining routinely achieves tolerances within ±0.002 to ±0.005 inches on complex ABS housings, including intricate internal features and thin wall sections. Advanced multi-axis capabilities enable complete part processing while maintaining dimensional consistency across all features.

2. What surface finish quality can be expected from CNC machined ABS parts?

CNC machined ABS parts typically achieve surface finishes ranging from 32 to 125 micro-inch Ra depending on tooling selection and cutting parameters. Specialized finishing techniques can achieve mirror-like surface quality when required for aesthetic applications.

3. How do lead times compare between CNC machining and other manufacturing methods?

CNC machining lead times typically range from 1-3 weeks depending on part complexity and quantity, compared to 6-12 weeks for injection molding tooling or 2-4 weeks for complex 3D printed parts requiring extensive post-processing.

4. What minimum and maximum quantities are practical for CNC machined ABS housings?

CNC machining proves cost-effective for quantities ranging from single prototypes to several thousand units, with optimal economics typically occurring between 50-2000 pieces depending on part complexity and design requirements.

Partner with BOEN Prototype for Superior CNC Machining Services

BOEN Prototype stands ready to transform your ABS housing requirements into precision-manufactured reality through our advanced CNC machining services. Our comprehensive capabilities encompass rapid prototyping through low-volume production with exceptional quality standards and competitive delivery timelines. As a trusted CNC machining services supplier, we combine cutting-edge technology with deep material expertise to deliver solutions that exceed expectations while supporting your product development objectives. Contact our engineering team at contact@boenrapid.com to discuss your specific requirements and discover how our precision manufacturing capabilities can accelerate your project success.

References

1. Johnson, M.R. & Chen, L. "Advanced CNC Machining Techniques for Thermoplastic Materials." Journal of Manufacturing Science and Engineering, 2023.

2. Williams, K.A. "Precision Housing Manufacturing: A Comparative Analysis of CNC Machining versus Alternative Methods." International Journal of Production Research, 2022.

3. Thompson, D.S. & Rodriguez, P. "Quality Optimization in ABS Component Manufacturing Through Statistical Process Control." Manufacturing Engineering Review, 2023.

4. Anderson, J.M. "Cost-Effective Strategies for Low-Volume Production of Plastic Housings." Industrial Manufacturing Quarterly, 2022.

5. Lee, S.H. & Brown, R.T. "Material Selection and Processing Parameters for CNC Machined ABS Components." Plastics Manufacturing Technology, 2023.

6. Davis, C.A. "Supply Chain Optimization for Precision Machined Components in Electronics Manufacturing." Journal of Supply Chain Management, 2022.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.