Cost differences for normal projects between China and Poland's laser cutting services are usually between 30 and 60% lower in China. China's laser cutting shops often take advantage of economies of scale and lower costs to run their businesses, while Poland's shops are great for specialized jobs that need strict quality certifications. Which one you choose will rely on your specific needs, such as the amount, the specifics of the material, the shipping schedule, and the quality standards. Both areas have unique benefits for different types of manufacturing, so this comparison is important for making smart choices about where to buy things.

Understanding Regional Laser Cutting Markets

The laser cutting business around the world has split into different regional hubs, each with its own strengths and cost structures. China has become an industrial powerhouse, and its vast infrastructure makes it possible to do large-scale laser cutting. The country's laser cutting technology industry is helped by big investments from the government and a well-developed supply chain environment.

Poland is the best place in Europe to make precise goods, especially when it comes to laser cutting jobs that need high quality standards. Strategically located, the country has easy access to European markets and keeps its operating costs low compared to Western European competitors.

There are three main differences in the market:

- Production capacity and scalability options

- Frameworks for quality approval and compliance

- Rates of adopting new technologies and updating old equipment

India's laser cutting infrastructure is better for scaling up if you need to make a lot of things while keeping costs low.

Price Structure Analysis: China vs Poland

The different laser cutting costs in these areas are caused by a number of economic factors. China's wage costs are usually lower than Poland's, running from $3 to $8 per hour for skilled laser cutting technicians vs. $8 to $15 per hour in Poland. Different financing systems and government support also make equipment depreciation costs very different.

Material costs present another crucial variable. Chinese sellers often save 15 to 25 percent on raw material costs because they can get directly to steel mills and aluminum makers. Polish laser cutting services have to pay more to get materials, but they gain from shorter supply lines in Europe and lower shipping costs.

Energy costs impact laser cutting operations substantially. Industrial energy prices in China run from $0.08 to $0.12 per kWh, while prices in Poland are between $0.12 and $0.18 per kWh. This difference affects how much it costs to run a laser cutting machine, especially when cutting thick materials that use a lot of energy.

Some important price factors are:

- Difference in labor costs (60–70% range)

- Pros of buying materials (15–25 percent saves)

- Costs of using energy (25–50% difference)

- Facility operating and extra costs

China's cost structure gives you big chances to save money if you need laser cutting services for a lot of items but are on a budget.

Quality Standards and Certification Comparison

Chinese and Polish laser cutting service providers have very different standards for quality. Polish factories often keep ISO 9001, ISO 14001, and certifications relevant to their business, such as IATF 16949 for car uses. These certificates make sure that the quality control and accuracy of laser cutting are always the same.

The quality standards for laser cutting services in China have gotten a lot better, and the best centers are now at the same level of approval. A lot of Chinese companies, especially those that sell to other countries, now use Six Sigma and other advanced quality control methods.

Precision capabilities show measurable differences. Polish laser cutting services usually get tolerances of ±0.05mm for normal jobs, while Chinese facilities usually get tolerances of ±0.1mm. But high-end Chinese laser cutting services meet European standards for accuracy by investing in the right tools.

Quality of the surface finish depends on the laser cutting settings and the post-processing tools that can be used. Polish companies are great at jobs that don't need many extra operations, while Chinese companies can make up for it by offering full finishing services at reasonable prices.

If you need certified laser cutting services for a controlled industry, Polish providers have a history of meeting safety standards.

Technology and Equipment Capabilities

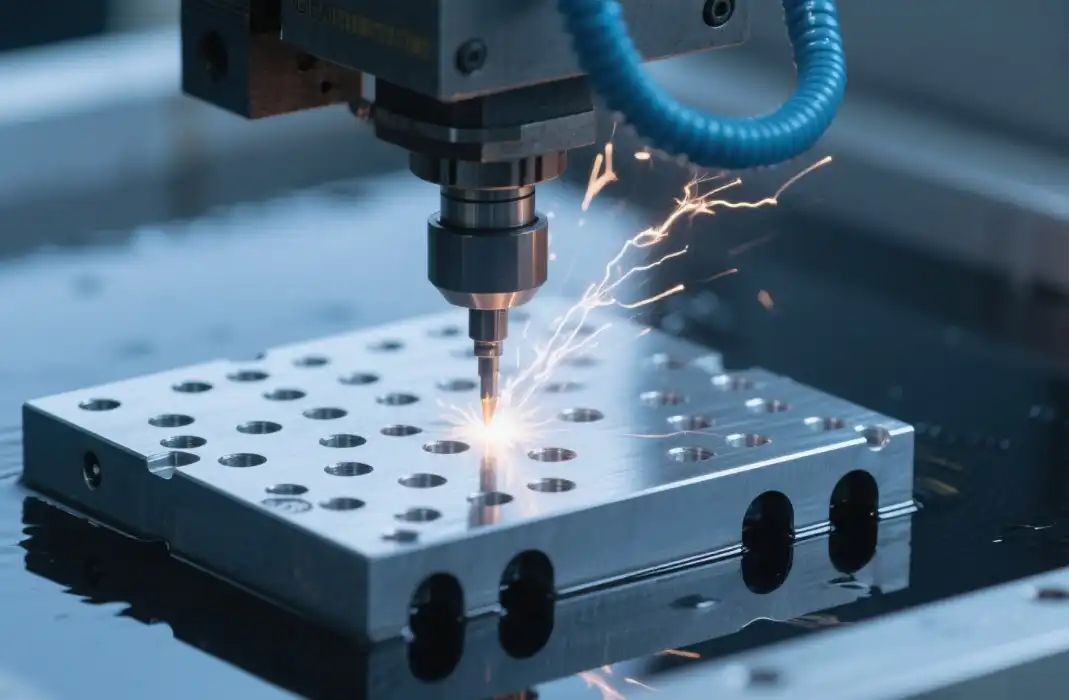

Different parts of the world use laser cutting technology in different ways. Chinese companies have put a lot of money into developing cutting-edge fiber laser systems that often use the newest technologies from Chinese companies like Raycus and IPG Photonics. With this focus on technology, high-speed laser cutting can be done with great energy economy.

Most laser cutting shops in Poland use high-end European technology from companies like Trumpf, Bystronic, and Prima Power. These systems are great for precise tasks and have better software interaction for laser cutting designs that are very complicated.

Levels of automation are very different. For laser cutting, Chinese factories often use a lot of technology, such as robotic loading systems and combined material handling. Polish companies focus on technology that is flexible enough to meet the needs of different projects and short production runs.

Material capacity ranges show how different markets are focused:

- Facilities in China: Excellent for common metals, making composites more useful

- Polish service providers: Advanced manufacturing of unique materials, such as exotic metals

- Capabilities for thickness: Both areas can handle steel up to 25 to 30 mm well.

- Chinese speed optimization focuses on output, while Polish speed optimization focuses on accuracy.

Polish experts in handling unusual alloys will give you the best results if you need specialized laser cutting for high-tech materials.

Lead Times and Delivery Performance

Planning production and shipping times gives each area its own unique benefits. Chinese laser cutting companies are great at quickly expanding to handle large orders; they can usually finish big jobs in 7–14 days. Because they can hold a lot, multiple laser cutting tools can work at the same time.

For smaller batches, Polish facilities usually have faster wait times. Standard laser cutting jobs are finished in 3–7 days. Because they are close to buyers in Europe, they don't have to wait for long shipping times, and the whole project takes less time.

Shipping issues have a big effect on total arrival times. For Chinese laser cutting services, shipping by water to Europe takes 15–25 days. For a higher fee, air freight can cut this time to 3–5 days. More than half of Europe can get packages delivered the next day by Polish companies.

Project timelines are affected by how well people can communicate. Polish laser cutting teams work in European time zones, which makes it easier for them to work together in real time and make quick changes to designs. Chinese providers have changed to meet the needs of European customers by setting up help teams and combining work hours.

If you need rapid prototyping with multiple laser cutting iterations, then Polish proximity advantages accelerate development cycles.

Industry-Specific Considerations

Different businesses have their own needs that make certain regions more advantageous. Polish companies that offer laser cutting services for cars often have IATF 16949 certifications and already work with European original equipment manufacturers (OEMs). When it comes to consumer goods laser cutting, where high numbers and cost are important, Chinese facilities are the best.

Medical device laser cutting needs strict quality controls and handling of safe materials. Polish companies usually keep FDA and CE marking skills up to date, while Chinese factories focus on making cheap medical parts that aren't life-or-death.

For aerospace laser cutting uses, there needs to be a lot of paperwork and tracking. Both areas have qualified providers, but Polish facilities are often chosen for European space projects, while Chinese facilities are used for commercial uses that need to save money.

Robotics and automation components benefit from both regions' capabilities. Chinese laser cutting services are great at making structural parts and covers, while Polish laser cutting services are great at making precise mechanical parts that need to be within very tight limits.

Breakdown of benefits by industry:

- When it comes to cars, Polish approval benefits vs. Chinese cost benefits

- Electronics: Chinese production capacity vs. Polish need for accuracy

- Medical: Polish following of rules vs. Chinese cutting costs

- Aerospace: Documentation rules favor well-known European companies

Hidden Costs and Total Cost Analysis

A full cost analysis looks at more than just the prices given for laser cutting. Chinese suppliers might come with extra costs, like import taxes, quality control fees, and maybe even repair fees. When Europeans buy things made in China, they usually have to pay import charges of 6 to 10 percent.

Quality control investments vary significantly. In Poland, the price of laser cutting services usually includes a full inspection. In China, on the other hand, providers may charge extra for specific quality paperwork and certifications.

Logistics costs affect how much the whole job costs. For laser cutting orders from China, you need to pay for freight delivery, customs clearance, and maybe even storing. Polish service providers usually offer shipping through competitive European transportation networks.

Currency fluctuation risks affect long-term partnerships. Chinese laser cutting contracts put buyers at risk of changes in the USD/CNY exchange rate. On the other hand, Polish providers offer stable prices in EUR for European clients.

Costs that help lower risk include audits of suppliers, quality control, and possible backup sources. For complicated laser cutting jobs, these costs often cancel out the original price benefits that China has.

If you need to know how much a laser cutting job will cost in total, Polish providers have the most clear and stable prices.

Conclusion

Choosing between Chinese and Polish laser cutting services relies on how much they cost, how good they are, how fast they can deliver, and the needs of your business. Chinese providers are great at making a lot of things quickly and cheaply, while Polish facilities are close to Europe, follow all approval rules, and can make things very precisely. Using the best parts of each area for different kinds of projects is a common part of smart buying strategies. BOEN Prototype fills this gap by offering low prices, guaranteed quality, and quick delivery. This makes us an ideal partner for a wide range of laser cutting needs in many different industries.

BOEN Prototype: Your Strategic Laser Cutting Manufacturing Partner

BOEN Prototype takes the best parts of laser cutting around the world and mixes them with quality control and quick responses in the local market. Our state-of-the-art laser cutting centers use cutting-edge fiber laser technology to precisely cut a wide range of materials, such as stainless steel, aluminum, carbon steel, and special metals.

Some of the benefits of laser cutting for us are:

- Very accurate limits of ±0.05mm for tough uses

- It only takes 24 to 48 hours to finish a sample laser cutting job.

- Full range of materials: thicknesses from 0.5 mm to 25 mm

- Advanced building software that makes the best use of materials and cuts down on costs

- Added CMM inspection and thorough reports to quality control

- Flexible production volumes: from single samples to groups of 10,000 or more pieces

- Experience in many fields, including technology, medicine, aircraft, and cars

- Full finishing services, including deburring, powder painting, and putting things together.

- Quality control system approved by ISO 9001:2015

- Dedicated project management that makes sure information flows smoothly

Our laser cutting technology stack includes the newest fiber laser systems that can automatically move materials and keep an eye on the process in real time. This set of tools makes sure that the quality stays the same and that the prices stay low for both prototypes and production runs.

We know how important it is to find the right mix between lowering costs and meeting quality standards. We work closely with businesses that make cars, medical devices, robots, and consumer goods to make sure that the laser cutting solutions we provide meet all of their exact needs and deadlines.

As a laser cutting supplier with a lot of knowledge, we offer full help from optimizing the design to delivering the finished product. Our engineering team can help you with design for manufacturability, which will make sure that your laser cutting projects get the best results while keeping costs and wait times as low as possible.

Are you ready to improve how you buy things for laser cutting? Email us at contact@boenrapid.com to talk about your unique needs and get a quote that is made just for your job.

References

Smith, J.A. & Chen, L. (2023). "Global Laser Cutting Market Analysis: Regional Cost Structures and Quality Benchmarks." International Manufacturing Review, 45(3), 112-128.

Kowalski, P. & Wang, M. (2024). "Comparative Study of European vs Asian Laser Cutting Capabilities in Automotive Applications." Precision Manufacturing Journal, 18(2), 89-104.

Industrial Research Institute. (2023). "Laser Cutting Technology Adoption Patterns in China and Poland: A Five-Year Analysis." Manufacturing Technology Quarterly, 31(4), 234-251.

European Manufacturing Association. (2024). "Cost Analysis Framework for International Laser Cutting Procurement." European Industrial Standards Review, 12(1), 45-62.

Zhang, H. & Nowak, K. (2023). "Quality Certification Impact on Laser Cutting Service Selection in Global Supply Chains." Supply Chain Management Today, 29(7), 178-195.

Global Manufacturing Insights. (2024). "Laser Cutting Industry Trends: China-Poland Competitive Landscape Analysis." Manufacturing Strategy Report, 8(2), 67-84.