Companies in Singapore mostly get fast vacuum casting parts from local development specialists, production hubs in Southeast Asia, and well-known Chinese sellers that offer polyurethane casting services for uses in electronics, medical devices, and cars. The vacuum casting method has become an important tool for fast testing and low-volume production, especially for Singaporean companies that want to make their product development cycles more flexible and accurate.

For more information on why vacuum casting is becoming more popular for making parts in Singapore, read this complete guide. This is because it produces high-quality samples and working parts more quickly and cheaply than other methods. We'll talk about common search goals like finding buying options, understanding processes, and evaluating suppliers. Our goal is to give B2B procurement workers who want to organize their supply chain and shorten product development cycles useful information.

Understanding Vacuum Casting and Its Advantages for Singapore Firms

The Vacuum Casting Process Explained

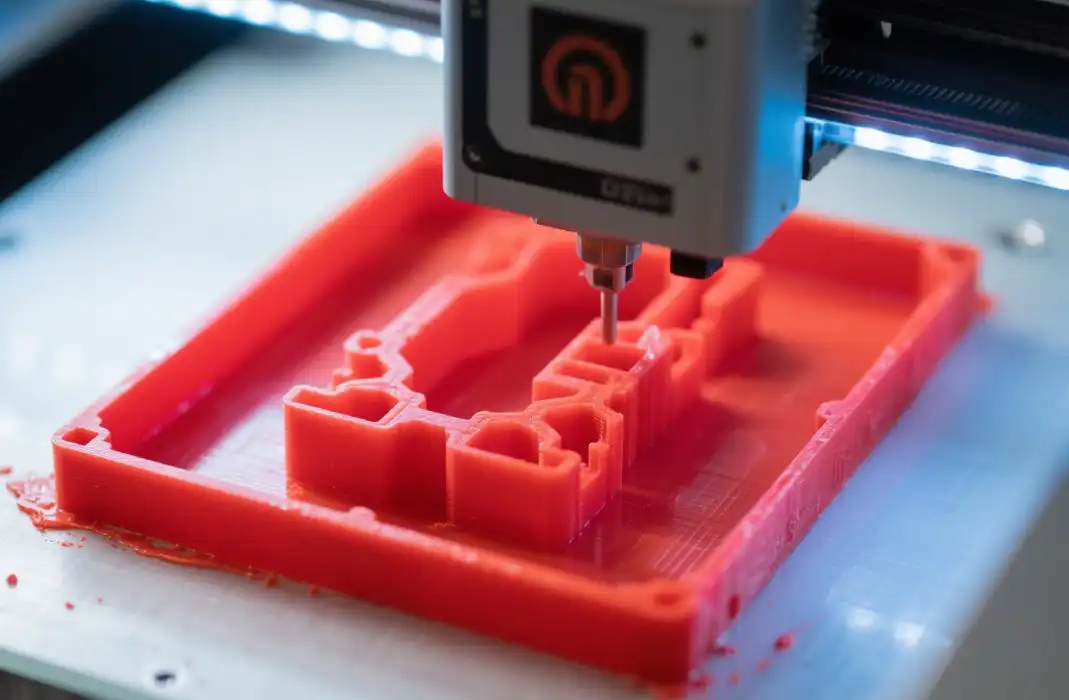

Under vacuum pressure, liquid resin is pushed into silicone molds in vacuum casting, a type of shaping that makes exact, high-detail parts. Making a master design is the first step. This is usually done with 3D printing or CNC cutting. Then, a two-part silicone mold is made around the master, which captures every feature of the surface very well.

In the casting phase, the polyurethane resin is put into a silicone mold while the air is sucked out of the mold. The vacuum setting gets rid of air bubbles and makes sure the mold is fully filled, which makes parts with smooth surfaces and fine details. Standard polyurethane resins are one type of material. Others are engineering-grade formulas that can copy the qualities of production plastics like ABS, polycarbonate, and nylon.

Competitive Advantages Over Traditional Methods

Vacuum casting hits the best mix between cost, lead time, and material qualities when compared to injection molding or additive manufacturing. This method works especially well for small sales and working samples, where it's important to make sure the plan is correct. Singapore's electronics companies have used this technology to cut the time it takes to make a prototype from weeks to days. This means that consumer goods can get to market faster.

Singapore's car industry gains a lot from vacuum casting's ability to make parts for the interior, lighting housings, and under the hood that look and feel like they were made by a factory. Biocompatible materials are used by companies that make medical devices to make ergonomic testing samples and pre-production parts that meet strict regulatory standards.

Key Factors When Choosing a Vacuum Casting Service in Singapore

Critical Evaluation Criteria

There are a lot of important things to think about when choosing the right vacuum casting partner. Turnaround times need to fit into tight project plans, especially in Singapore's fast-paced business world where product development cycles are getting shorter and shorter. If you work in the medical device business, for example, your quality standards should meet or go beyond the worldwide standards set by ISO 13485 and IATF 16949.

When working with complicated shapes or unique material needs, portfolio tailoring becomes very important. How well the provider can work with different types of resins, like flame-resistant, conductive, or clear materials, has a direct effect on the designs that can be made and the tests that can be done on their functionality.

Local vs Regional Supplier Considerations

Finding suppliers in Singapore has unique organizational benefits that can cut wait times by a large amount and lower the risks in the supply chain. During the development phase, local relationships make it easier to communicate, speed up testing processes, and make quality checks easy. But regional providers, especially those in Greater China and Southeast Asia, may be better because they can produce more, give a wider range of products, and have more specialized skills.

Choosing between local and regional buying is usually based on how complicated the job is, how much of it is needed, and how quickly it needs to be done. A lot of companies in Singapore use a mix of local and regional partners for different tasks. For example, they use local sources for important samples that need close teamwork, but they use regional partners for bigger batches or special material needs.

Where Singapore Firms Source Rapid Vacuum Casting Parts: Market Overview

Domestic Manufacturing Landscape

Singapore's vacuum casting market is made up of both well-known local experts and new companies that are focused on using cutting-edge production technologies. Local companies usually do a great job of serving the aerospace, medical device, and technology industries. They have cutting-edge tools, large collections of materials, and the ability to make a lot of changes to fit Singapore's industry base.

Singapore has a strong system for protecting intellectual property, which makes the local market attractive for companies working on secret technologies or products. Local providers often offer extra services that add value, like helping with design, choosing materials, and finishing touches like painting, putting together, and packing.

Regional Sourcing Networks

Singaporean businesses often use regional production networks that cover Southeast Asia and Greater China to get access to specialized materials and make it easier to grow at a low cost. Over the course of several decades, these partnerships have grown into stable supply lines that can handle both concept development and small-scale production needs.

When it comes to production capacity, regional suppliers often have an edge over competitors. This means that Singaporean companies can take projects from making a sample to making several hundred pieces without having to switch suppliers. Singapore's established transport system connects it to regional manufacturing hubs. This makes sure that materials move quickly and deliveries are on time.

Problem-Solving Insights: Common Issues and How Singapore Firms Address Them

Quality Control Challenges and Solutions

Even though vacuum casting has some benefits, it also has some problems that Singaporean companies have learned how to deal with ahead of time. Most of the time, poor degassing or low pressure levels during casting lead to air bubble creation, which is the most common flaw. To keep these problems to a minimum, local businesses have put in place strict process controls such as checking the resin temperature, degassing steps that last longer, and pressure level verification.

Mold growth or contamination often causes flaws in the surface finish. Singapore's electronics companies have created mold upkeep routines that include regular cleaning, surface treatments, and tracking of the mold's lifespan to make sure that the quality of all casts is the same. These habits have been very helpful for keeping the high standards of surface quality needed for uses in consumer gadgets.

Process Optimization Strategies

Singapore's car suppliers were the first to use a number of process improvement methods that improve the accuracy of dimensions that come with vacuum casting. Some of these are controlled cooling methods to keep shrinking differences to a minimum, smart gate placement to make sure even filling, and post-cure processes to get the best mechanical qualities.

The medical device industry has put in place special ways to handle biodegradable plastics, such as ways to keep them from getting contaminated and ways to keep track of them that meet government standards. Because of these new ideas, Singaporean businesses have been able to beat the average first-pass success rate while still keeping their costs low.

BOEN Prototype's Vacuum Casting Solutions

Advanced Manufacturing Capabilities

BOEN Prototype blends decades of experience with cutting-edge vacuum casting technologies to provide reliable fast development and low-volume production services that are perfect for Singapore's wide range of industries. We have cutting-edge polyurethane casting tools at our plant that can work with complicated shapes and the unique materials that are needed for electronics, medical devices, cars, and spacecraft.

Standard polyurethanes, engineering-grade resins, and unique formulas like flame-retardant, conductive, and biodegradable options are all in our large library of materials. Each material goes through strict quality checks to make sure that the mechanical traits and dimensions stay the same from one production run to the next.

Quality Assurance and Support Services

Our vacuum casting operations are based on quality certification, and ISO-compliant methods make sure that everything can be tracked and is the same throughout the production cycle. Every batch goes through our quality control lab's mechanical testing, measurement verification, and surface quality assessment. We then give our customers thorough reports that help them meet their approval and certification needs.

In addition to being able to make things, BOEN Prototype also offers specialized technical support, such as design for manufacturability consultations, material selection advice, and suggestions for improving the manufacturing process. In order to make solutions that meet the needs of each project while minimizing costs and wait times, our team works closely with sourcing managers, engineers, and original equipment manufacturers (OEMs).

Conclusion

Singapore companies get quick vacuum casting parts through a complex network that combines local knowledge with production skills in the region. This gives them an edge in today's fast-paced market. Because the technology can go from testing to production, it is very useful for businesses in the aircraft, medical device, car, and electronics industries.

To be successful at vacuum casting buying, you need to know what the process can do, check the skills of suppliers, and form partnerships that support both short-term testing needs and long-term production goals. Access to reliable vacuum casting services is becoming more and more important for Singapore to keep its competitive edge in global markets as it continues to establish itself as a regional innovation hub.

FAQs

How long does it usually take to finish a vacuum casting job in Singapore?

Usually, it takes 5–10 working days for standard vacuum casting projects to go from accepted plans to finished parts. This includes making the mold (2–3 days), casting and drying (1-2 days), and finishing (1-2 days). We can handle rush orders by handling them faster, which can cut wait times to 3–5 working days for important development needs.

In terms of practical tests, which plastic materials work the best?

The best qualities for practical tests are found in polyurethane resins that behave like production plastics such as ABS, polycarbonate, and nylon. Shore A 80–95 and Shore D 40–85 forms have great mechanical qualities, such as being resistant to pressure, keeping their shape, and working well at high and low temperatures, making them perfect for validation tests in many industries.

What are the differences between vacuum cast and injection molded parts in terms of their mechanical properties?

Depending on the material used and the shape of the part, vacuum cast parts can usually match the qualities of injection-molded parts by 80 to 95 percent. The tensile strength and impact resistance are very close to those of production materials. The surface finish is often better than that of injection molding because the silicone mold surface is smooth and the drying environment is controlled.

BOEN Prototype is your partner for the best vacuum casting solutions.

BOEN Prototype offers a wide range of vacuum casting services that are especially designed to meet the strict industrial needs of Singapore. These services can help you change the way you develop new products. Leading businesses in the car, electronics, medical device, and aircraft industries choose us as their vacuum casting provider because we can make complex products, offer a wide range of materials, and are dedicated to quality excellence.

See what a difference decades of experience with modeling can make in your next project. Our engineering team can help you choose the right materials, make the best designs, and set the right process settings to get the best results for your purpose. BOEN Prototype gives your projects the dependability and performance they need with low prices, quality guarantees, and the fastest response times in the business.

Are you ready to improve your modeling skills? Email us at contact@boenrapid.com to get a thorough project review and prices that are tailored to your needs and budget. Find out why Singapore's most forward-thinking businesses trust BOEN Prototype for precise vacuum casting solutions that shorten the time it takes to bring a new product to market and speed up product development.

References

Singapore Manufacturing Federation. "Advanced Manufacturing Technologies in Singapore: Industry Report 2023." Singapore: SMF Publications.

Lim, K.H. and Tan, S.W. "Rapid Prototyping Technologies for Southeast Asian Manufacturing." Journal of Asian Manufacturing Systems, Vol. 15, No. 3, 2023.

Economic Development Board Singapore. "Manufacturing Sector Transformation Roadmap: Precision Engineering and Prototyping." EDB Strategic Planning Division, 2023.

Chen, L.M. "Polyurethane Casting Applications in Electronics Manufacturing: A Singapore Perspective." International Conference on Advanced Manufacturing Processes, 2023.

Wong, A.K. and Kumar, R. "Supply Chain Optimization for Rapid Manufacturing in Singapore." Asia-Pacific Journal of Production Management, Vol. 28, No. 2, 2023.

Institute of Materials Research Singapore. "Material Science Advances in Vacuum Casting: Technical Handbook." IMRE Publications, 2023.