How Rapid Tooling Supports DFM Strategies?

Design for Manufacturability (DFM) plans are changed by rapid tooling, which lets companies make tools that are ready for production in weeks instead of months. This new way of doing things helps DFM goals by speeding up design approval, making prototypes cheaply, and allowing for flexible production processes. Companies can quickly change designs, find possible manufacturing problems early, and make parts that are best for mass production while still meeting quality standards and lowering total development costs by using rapid tooling methods like soft tooling and metal molds.

Understanding Rapid Tooling and Its Role in DFM

Rapid shaping includes advanced manufacturing technologies that make it possible to make working production tools in a lot less time than with traditional methods. Some of these technologies are direct tool making, fast injection molding, and soft casting. They use materials like aluminum alloys, high-performance plastics, and special steel grades. The rapid tooling process usually starts with analyzing a CAD model. This is followed by optimizing the tool design, choosing the right material, and speeding up the production process with methods such as CNC cutting or additive manufacturing.

When rapid tooling is used with DFM methods, it provides mutual benefits that go beyond just saving time. Design engineers can test their manufacturing ideas by making working prototypes with tools made for production. This can show problems that might not be seen during regular prototype development. Teams can improve part shapes, change material specs, and make the best tool designs with this early approval feature before investing in expensive production tools.

The choice of material is very important for how well and how long rapid tooling works. Aluminum alloys are great for injection molding uses that need small to medium production numbers because they are good at transferring heat and can be machined easily. High-performance plastics are cheap options for low-volume uses and can be used in complicated shapes that would be hard to make with regular materials. Rapid tools can have steel plates added to them to make places that get a lot of use last longer while keeping the cost benefits.

Key Technologies Driving Rapid Tooling Innovation

Advanced CNC cutting lets you make exact tools with tight specs and better surface finishes. Five-axis machining centers can make tools with complicated shapes in just one setup, which cuts down on wait times and improves accuracy. High-speed cutting methods remove material quickly while keeping the dimensions exactly the same. This is especially helpful for making metal tools.

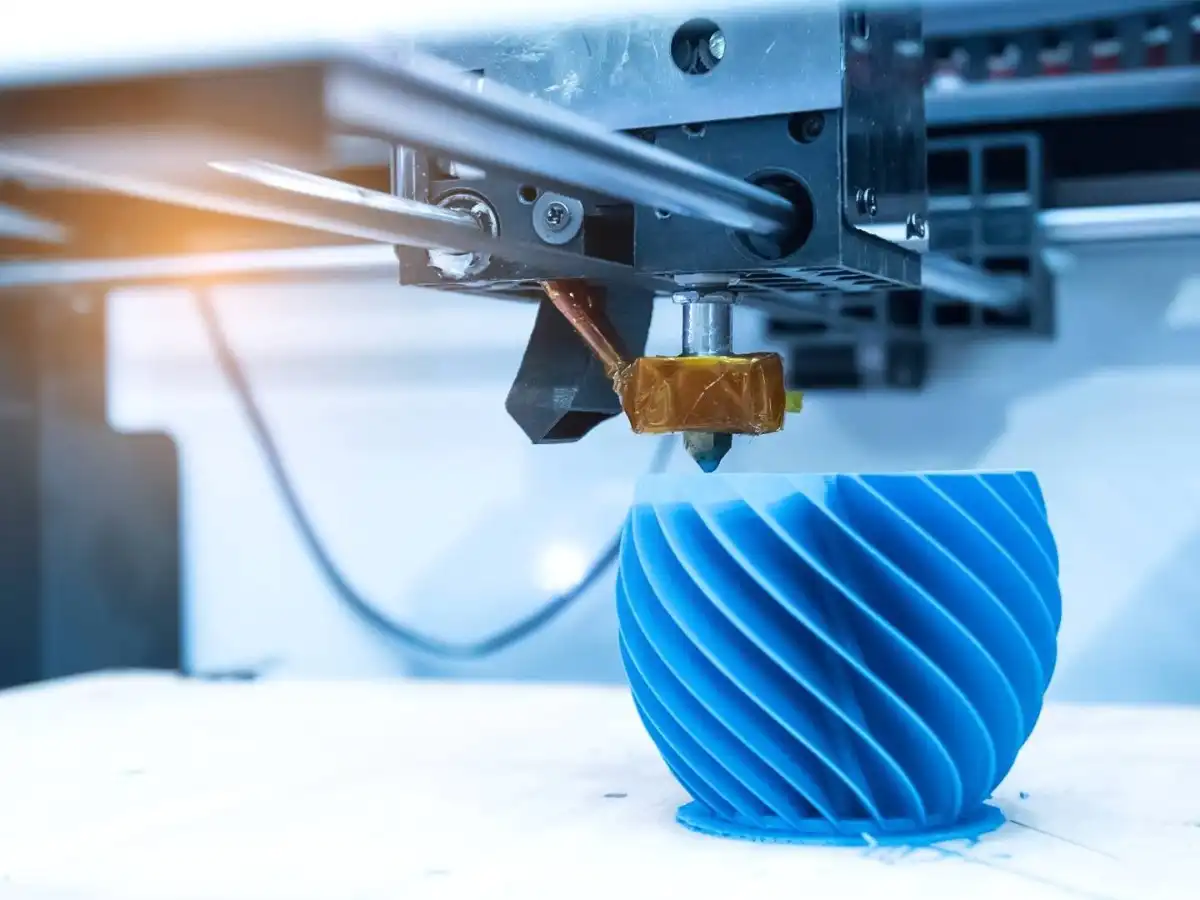

Some additive manufacturing techniques, like selective laser sintering and stereolithography, are better than others at making it possible to make complex internal shapes and curved cooling channels that can't be made with traditional cutting. These features improve the performance of the tool while easing production restrictions. This makes it possible for new DFM methods that weren't possible before.

Traditional Tooling vs Rapid Tooling: Key Differences and Implications for DFM

Traditional ways of making tools use sharpened steel and long, complicated grinding steps that can take 12 to 20 weeks to finish. With these methods, long-lasting tools and the ability to make a lot of things are valued more than freedom and response. Usually, traditional tools cost a lot more up front, but they last a long time and can make millions of parts with uniform quality.

Rapid tooling methods put speed and freedom ahead of final durability, so based on the complexity and requirements, a tool can be finished in 2 to 6 weeks. Even though fast tools can't make as much as traditional tools, they are very useful for quickly getting a product on the market, making sure the plan works, or making small to medium batches of products. When making less than 50,000 units, the cost-per-part analysis usually points toward rapid tooling. This is especially true when overall project timelines and stocking needs are taken into account.

One of the best things about rapid tooling in DFM applications is that it cuts down on lead times. While standard hardware is still being built, engineering teams can try designs, make sure they work, and improve output parameters. This time advantage lets you do more than one design change in the time it normally takes to do one, which helps with more thorough optimization and lowering risk.

Strategic Decision Framework for Tooling Selection

The production number needs are the main factor that affects the choice of tools. When less than 100,000 parts need to be made, rapid tooling works best, while standard tooling becomes more cost-effective as the number of parts needed rises. But because the market isn't sure what will happen and the product has a limited lifecycle, rapid tooling may be preferred, even for high-volume uses, so that the company can adapt to changes in demand.

Tooling choices are also affected by how hard the design is to change and how likely it is to be changed. Rapid tooling's natural freedom is advantageous for products that are still in development or whose market acceptance is unsure. When companies use traditional tools, they have to stick to certain design guidelines that are expensive to change. But with fast tools, they can be updated or changed as needs change without spending a lot of money.

Time-to-market pressures often come before pure cost concerns. This is why rapid tooling is appealing even when more standard options might have lower per-unit costs. Getting into a market earlier and making more money often makes up for higher per-part tooling costs. This is especially true in competitive markets where time benefits lead to bigger market shares.

Practical Applications of Rapid Tooling in DFM for Global B2B Clients

Uses in the automotive business show how flexible rapid tooling is for making different kinds of parts and meeting different production needs. Rapid tooling makes it possible to make design changes throughout development cycles, which is helpful for interior trim parts, lighting housings, and electrical cases. Manufacturers of electric vehicles especially like rapid tooling for making samples of battery housings and charging system parts, where designs change quickly and production numbers stay low during the early stages of introducing new products to the market.

For the production of lightweight structural parts and specialized housings that need a lot of testing and approval, aerospace and military uses use rapid tooling. For thorough testing of part performance in real-world situations, the ability to make working prototypes using production-intent methods is essential. Manufacturers of unmanned aerial vehicles use rapid tooling to make complicated aerodynamic surfaces and electrical housings that need to be precisely measured and have high-quality surfaces.

Biocompatibility, cleaning compatibility, and practical concerns make making medical devices very difficult. They need to be tested and improved over and over again. Rapid tooling lets companies that make medical devices make working versions for testing in humans, while still letting them make changes to the designs based on user feedback and government rules. The technology is especially helpful for making better surgery instruments, because better ergonomics have a direct effect on how well users do their jobs and how well patients do.

Consumer Electronics and Smart Device Integration

The consumer electronics industry is a good example of how rapid tooling can help with short product lifecycles and frequent design changes. Manufacturers of smart home devices are always under pressure to add new features, make their products look better, and cut costs all while meeting tight start dates. Rapid tooling meets these needs by letting housing designs, button systems, and connecting connections be changed quickly and without spending a lot of money.

The production of enclosures is a very important task where rapid tooling actually works better. Electronic housings need to be able to handle complicated internal plans, block electromagnetic interference, look good, and be manufactured in a way that keeps costs low. With rapid molding, designers can make working versions of these requirements to make sure they are met before investing in production tools.

Integrating Rapid Tooling in the Procurement Process

To get rapid tooling services that work, you need to carefully evaluate possible providers based on their technological know-how, quality control systems, and project management skills. Leading makers keep up-to-date cutting tools like five-axis CNC centers, precise measuring tools, and climate-controlled production areas that make sure quality and accuracy of measurements are always maintained.

Communication methods and project management tools have a big effect on how well a rapid tooling project turns out. Suppliers should keep project documents up to date and easy to find, and they should offer expert advice throughout the development process. Specification papers that are easy to understand and include things like material standards, range goals, and delivery dates are the building blocks for good relationships and consistent results.

Quality management systems and certificates show that a provider is dedicated to uniform processes and ongoing growth. Structured quality management is shown by ISO 9001 certification, while industry-specific certifications, like AS9100 for aircraft uses or ISO 13485 for medical products, show that the company has the right knowledge and skills to follow the rules.

Vendor Evaluation and Selection Criteria

An evaluation of technical skills should look at both the technical know-how and the tools that can be used. Suppliers that offer design optimization services in-house can give useful information that can help make tools work better and lower output risks. Having worked with similar uses and materials before gives you faith in the ability to complete a job and solve a problem.

Geography affects the operations of a project, how well people can communicate, and how resilient the supply chain is. When it comes to contact, shipping costs, and project control, regional suppliers often have an edge over global suppliers. However, global suppliers may offer cost benefits or specific skills that aren't available locally. A balanced review looks at the full cost of a project, which includes things like communication, scheduling, and risk factors that go beyond the price of tools.

BOEN Prototype: Your Rapid Tooling Partner for DFM Excellence

BOEN Prototype specializes in providing complete rapid tooling solutions that improve DFM strategies in a wide range of businesses. We know a lot about CNC machining, fast injection molding, compression molding, and advanced 3D printing technologies that help make tools quickly and make sure designs work. Companies that make cars, medical devices, spacecraft, and consumer electronics all come to us when they need quick and efficient tooling solutions.

As part of our combined method, we offer rapid tooling along with a deep understanding of materials and process improvement. From the first design meeting to the delivery of the end tool, we offer full support that helps our clients get the best results in production. Our flexible manufacturing options can handle different production rates and time frames, and our quality control systems make sure that results are always the same.

Some of the technical skills they have are precision CNC machining centers that can make complicated metal and steel tools with tight specs and high-quality surface finishes. Our fast injection molding services make it easy to test plastic part designs quickly using materials and methods that are intended for production. Services that work well together, like vacuum casting and metal pressing, give you more choices for certain applications.

The factory has climate-controlled rooms and high-tech quality control systems that make sure the products are the right size and work the same way every time. Together with our clients, our engineering team makes sure that the designs of our tools are the best they can be for each purpose, material, and output need. This interactive method helps find problems early on and makes tools work better and last longer.

Conclusion

Rapid tooling changes DFM tactics by making making tools and validating designs much faster, more flexible, and less expensive than ever before. Manufacturers can quickly change designs, make sure their ideas about manufacturing are correct, and improve production processes with this technology before they spend a lot of money on expensive traditional tools. The ability of rapid tooling to support flexible development processes and responsive production strategies is useful in many industries, including cars and aircraft, medical devices, and consumer electronics. As market changes speed up even more, companies that successfully incorporate rapid tooling into their DFM methods will stay ahead of the competition by utilizing faster innovation processes and more flexible supply chain strategies.

FAQ

What are the main advantages of rapid tooling in supporting DFM strategies?

Rapid tooling helps DFM strategies by speeding up design approval, lowering development costs, and giving manufacturers more options for how they can make things. The technology lets tool designs be changed quickly, possible manufacturing problems be found early, and production processes be tested without spending a lot of money. Because of these benefits, engineering teams can improve designs more fully while cutting down on project risks and timelines.

How does rapid tooling significantly shorten production lead times compared to traditional methods?

Through improved processes and advanced production technologies, rapid tooling cuts lead times from the usual 12 to 20 weeks to 2 to 6 weeks. This method gets rid of a lot of the time-consuming steps that are needed for standard tools, like long heat treatment processes and complicated sets for cutting. This speeding up lets companies get into new markets faster and makes product creation processes more flexible.

What key factors should procurement professionals consider when choosing rapid tooling suppliers?

Technology skills, quality control systems, communication methods, and knowledge in the related business are all important factors. Suppliers should show that they can do advanced machining, have the right certifications, and have a history of success in similar projects. Location, clear pricing, and the ability to provide professional help all have a big effect on the success of a partnership and the results of a project.

Ready to Transform Your DFM Strategy with BOEN Prototype

With cutting-edge rapid tooling solutions, BOEN Prototype is ready to change the way you make things. As a reliable rapid tooling maker, we offer top-notch quality, speed, and technical know-how that shortens the time it takes to create new products. Our wide range of skills in CNC machining, injection casting, and advanced development make it easy to add rapid tooling to your DFM strategy. Email our expert team at contact@boenrapid.com to talk about your unique needs and find out how our rapid tooling services can help you make better products while cutting costs and time.

References

Gibson, Ian, David Rosen, and Brent Stucker. "Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing." Springer Science & Business Media, 2014.

Pham, Duc Truong, and Rajkumar S. Dimov. "Rapid Manufacturing: The Technologies and Applications of Rapid Prototyping and Rapid Tooling." Springer Science & Business Media, 2001.

Volpato, Neri, et al. "Manufacturing and Design for Manufacturability in Rapid Tooling Applications." International Journal of Advanced Manufacturing Technology, 2019.

Levy, Gideon N., Ralf Schindel, and J. P. Kruth. "Rapid Manufacturing and Rapid Tooling with Layer Manufacturing Technologies: State of the Art and Future Perspectives." CIRP Annals Manufacturing Technology, 2003.

Rosochowski, Andrzej, and Antoni Matuszak. "Rapid Tooling: The State of the Art." Journal of Materials Processing Technology, 2000.

Wohlers, Terry, and Tim Caffrey. "Wohlers Report: 3D Printing and Additive Manufacturing State of the Industry Annual Worldwide Progress Report." Wohlers Associates, 2020.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.