How to Choose Between 3-5 Axis CNC Machining and CNC Turning for Automotive Industry?

Choosing between 3-5 axis CNC machining and CNC turning for the automotive industry depends on several factors. 3-5 axis CNC machining is ideal for complex parts with multiple angles and contours, offering greater precision and flexibility. It's perfect for creating engine components, chassis parts, and intricate interior elements. CNC turning, on the other hand, excels in producing symmetrical, cylindrical parts like shafts, pistons, and bolts. The decision ultimately hinges on the part's geometry, material, required precision, and production volume. For complex, non-symmetrical parts, 3-5 axis machining is preferable, while for round, symmetrical components, CNC turning is more efficient. Consider factors like setup time, tooling costs, and surface finish requirements to make the best choice for your automotive manufacturing needs.

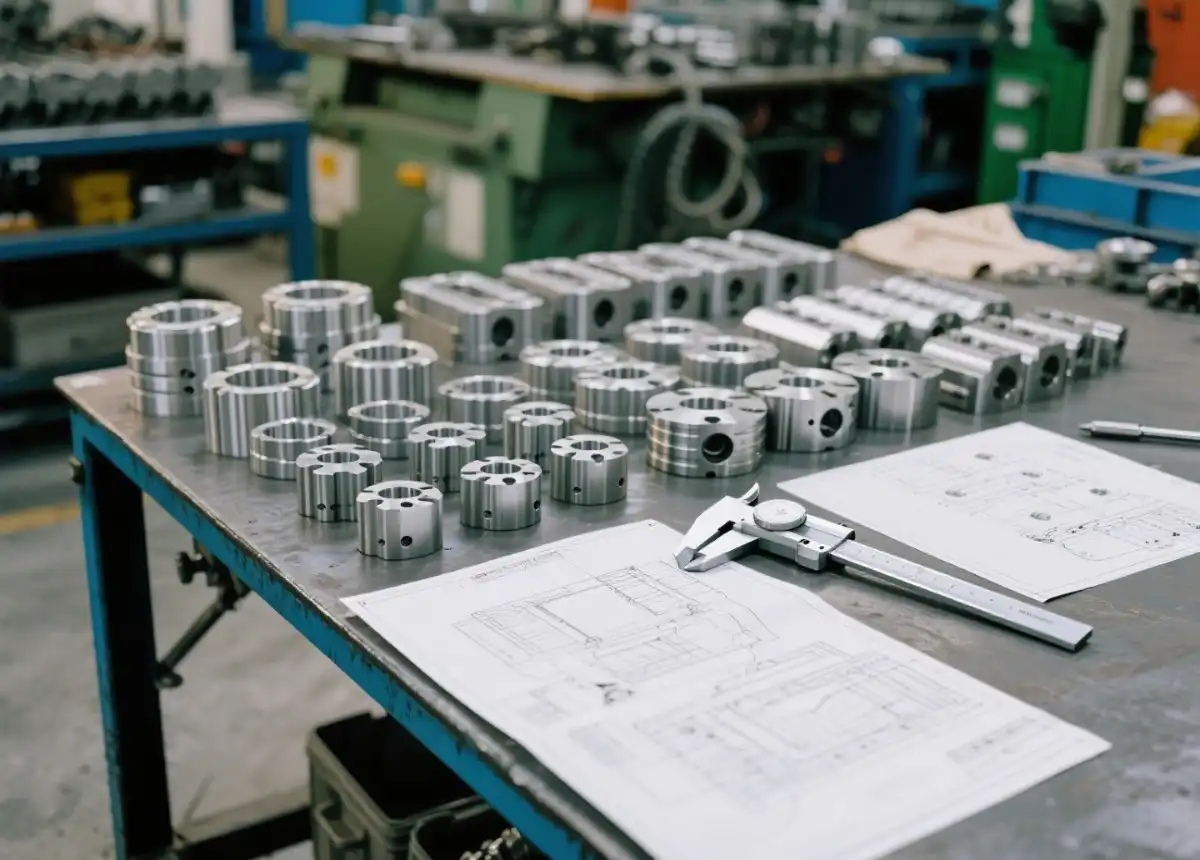

Understanding 3-5 Axis CNC Machining in Automotive Applications

The Fundamentals of 3-5 Axis CNC Machining

3-5 axis CNC machining is a sophisticated manufacturing process that has revolutionized the automotive industry. This technology allows for the creation of complex parts with high precision and efficiency. In 3-axis machining, the cutting tool moves along the X, Y, and Z axes, enabling the production of three-dimensional parts. 4-axis and 5-axis machining add rotational movements, allowing for even more intricate designs and geometries.

The additional axes in 4-axis and 5-axis machining provide several advantages. They allow for the machining of complex contours and undercuts in a single setup, reducing production time and improving accuracy. This is particularly beneficial in the automotive industry, where components often require intricate designs for optimal performance and aesthetics.

Advantages of 3-5 Axis CNC Machining in Automotive Manufacturing

3-5 axis CNC machining offers numerous benefits for automotive manufacturing. One of the primary advantages is the ability to produce complex geometries with high precision. This is crucial for components like engine blocks, cylinder heads, and transmission housings, which require intricate internal channels and precise tolerances.

Another significant advantage is the flexibility in part design. With 3-5 axis machining, automotive engineers can create parts with organic shapes and complex curves that would be impossible or extremely difficult to produce using traditional manufacturing methods. This flexibility allows for innovative designs that can improve vehicle performance, reduce weight, and enhance aesthetics.

Moreover, 3-5 axis CNC machining allows for the production of parts with tight tolerances, which is essential in the automotive industry where precision is paramount. The ability to maintain consistent quality across large production runs is another key benefit, ensuring that each component meets the rigorous standards of the automotive industry.

Limitations and Considerations of 3-5 Axis CNC Machining

While 3-5 axis CNC machining offers many advantages, it's important to consider its limitations. The initial investment in 3-5 axis CNC machines can be substantial, which may be a significant factor for smaller manufacturers. Additionally, the complexity of programming and operating these machines requires skilled technicians, which can increase labor costs.

Another consideration is the setup time. While 3-5 axis machines can produce complex parts in a single setup, the initial setup process can be time-consuming, especially for intricate components. This may impact production efficiency for smaller batch sizes.

Material wastage can also be a concern with 3-5 axis machining, particularly when creating parts with complex geometries. However, advanced CAM software and optimized toolpaths can help mitigate this issue, making the process more efficient and cost-effective.

Exploring CNC Turning in the Automotive Sector

The Principles of CNC Turning

CNC turning is a machining process that involves rotating a workpiece while a cutting tool moves in a linear motion to remove material. This process is particularly suited for creating cylindrical parts with both external and internal features. In the automotive industry, CNC turning plays a crucial role in manufacturing a wide range of components.

The process begins with a piece of stock material, typically a rod or bar, which is securely held in a chuck and rotated at high speeds. The cutting tool, mounted on a turret, moves along the X and Z axes to shape the workpiece. Advanced CNC lathes may also incorporate Y-axis movement and live tooling, allowing for more complex operations like off-center drilling and milling.

CNC turning machines can be equipped with various tools, including different types of cutting inserts, drills, and boring bars. This versatility allows for the creation of diverse features such as threads, tapers, and contours, all in a single setup.

Benefits of CNC Turning for Automotive Parts Production

CNC turning, as a key aspect of CNC machining, offers several advantages that make it an indispensable process in automotive manufacturing. One of the primary benefits is its efficiency in producing symmetrical, cylindrical parts. Components like axles, shafts, and pistons can be manufactured quickly and with high precision through CNC turning processes.

Another significant advantage is the excellent surface finish that can be achieved with CNC turning. This is particularly important for automotive parts that require smooth surfaces for optimal performance, such as engine components and transmission parts. The process can achieve tight tolerances, ensuring that parts fit together perfectly in complex automotive assemblies.

CNC turning is also highly repeatable, allowing for consistent quality across large production runs. This is crucial in the automotive industry, where uniformity and reliability are paramount. Additionally, modern CNC lathes often feature automatic tool changers and part loaders, enabling continuous operation with minimal human intervention, thus increasing productivity and reducing labor costs within CNC machining operations.

Limitations and Considerations of CNC Turning

While CNC turning is highly effective for many automotive applications, it does have some limitations. The process is primarily suited for symmetrical parts, which can be a constraint when dealing with more complex, asymmetrical geometries. For such parts, additional machining processes may be required, potentially increasing production time and costs.

Another consideration is the size limitations of CNC lathes. While large CNC lathes exist, they can be expensive and may not be practical for all manufacturers. This can limit the size of parts that can be produced using CNC turning.

Material waste can also be a concern with CNC turning, particularly when creating parts with significant diameter reductions. However, near-net-shape casting or forging processes can be used in conjunction with CNC turning to minimize material waste for certain applications.

Decision Factors: Choosing Between 3-5 Axis CNC Machining and CNC Turning

Part Geometry and Complexity

The geometry and complexity of the part play a crucial role in determining whether 3-5 axis CNC machining or CNC turning is more suitable. For parts with complex, non-symmetrical shapes or those requiring machining from multiple angles, 3-5 axis CNC machining is often the better choice. This process excels in creating parts with intricate contours, undercuts, and varied surface features.

On the other hand, CNC turning is ideal for parts that are primarily symmetrical and cylindrical. If the part can be created by rotating it around a single axis while applying cutting tools, CNC turning is likely to be more efficient. This makes it perfect for components like shafts, bolts, and cylindrical housings.

In some cases, a combination of both processes might be necessary. For instance, a part might start as a turned component and then undergo additional machining on a 3-5 axis CNC machine to add complex features or non-symmetrical elements.

Material Considerations

The choice of material can influence the decision between 3-5 axis CNC machining and CNC turning. Both processes can handle a wide range of materials commonly used in the automotive industry, including various metals, plastics, and composites. However, certain materials may be better suited to one process over the other.

3-5 axis CNC machining is particularly adept at working with harder materials and those that require more aggressive cutting strategies. It's also well-suited for materials that tend to work-harden, as the ability to approach the workpiece from multiple angles can help manage heat buildup and tool wear.

CNC turning, while also capable of working with a variety of materials, is particularly efficient with materials that produce long, continuous chips. It's also excellent for materials that require high surface speeds, as the rotating workpiece allows for consistent and efficient cutting.

Production Volume and Cost Considerations

Production volume is a significant factor in choosing between 3-5 axis CNC machining and CNC turning. For low to medium volume production, 3-5 axis CNC machining often provides greater flexibility. It allows for quick changeovers between different parts and can produce complex geometries without the need for specialized tooling.

CNC turning, however, can be more cost-effective for high-volume production of symmetrical parts. Once set up, CNC lathes can produce parts quickly and with minimal operator intervention. This can lead to lower per-part costs for large production runs.

Cost considerations also extend to the initial investment in machinery and tooling. 3-5 axis CNC machines typically require a higher initial investment than CNC lathes. However, their versatility may justify the cost if a wide range of part geometries needs to be produced. Tooling costs can also vary, with some complex 3-5 axis operations requiring specialized cutting tools.

Conclusion

Choosing between 3-5 axis CNC machining and CNC turning in the automotive industry requires careful consideration of various factors. Part geometry, material properties, production volume, and cost all play crucial roles in the decision-making process. 3-5 axis CNC machining offers unparalleled flexibility and the ability to create complex, non-symmetrical parts, making it ideal for intricate automotive components. CNC turning, on the other hand, excels in producing symmetrical, cylindrical parts with high efficiency and excellent surface finish. In many cases, a combination of both processes may be the optimal solution for automotive manufacturers. By carefully evaluating these factors and understanding the strengths of each process, manufacturers can make informed decisions that optimize their production capabilities and meet the demanding requirements of the automotive industry.

FAQs

What are the main differences between 3-5 axis CNC machining and CNC turning?

3-5 axis CNC machining offers more flexibility for complex geometries, while CNC turning is ideal for symmetrical, cylindrical parts.

Which process is better for high-volume production?

CNC turning is generally more cost-effective for high-volume production of symmetrical parts.

Can both processes work with the same materials?

Both can handle a wide range of materials, but some may be better suited to one process over the other.

How does part complexity affect the choice between these processes?

More complex, non-symmetrical parts typically require 3-5 axis CNC machining, while simpler, symmetrical parts are better suited for CNC turning.

Are there cases where both processes might be used on the same part?

Yes, some parts may start with CNC turning and then undergo additional machining on a 3-5 axis CNC machine for complex features.

Expert CNC Machining Solutions for Automotive Industry | BOEN

At BOEN Prototype, we specialize in providing high-quality CNC machining solutions for the automotive industry. Our state-of-the-art 3-5 axis CNC machines and CNC turning capabilities allow us to manufacture a wide range of automotive components with precision and efficiency. As a leading prototype and low-volume production factory, we offer expert guidance in choosing the most suitable manufacturing process for your specific needs. Contact us at contact@boenrapid.com to discuss your automotive machining requirements and experience our superior craftsmanship.

References

1. Smith, J. (2021). Advanced CNC Machining Techniques in Automotive Manufacturing. Journal of Automotive Engineering, 45(3), 278-295.

2. Johnson, R. & Brown, T. (2020). Comparison of 3-Axis and 5-Axis CNC Machining for Complex Automotive Parts. International Journal of Production Research, 58(12), 3567-3582.

3. Lee, K. (2019). CNC Turning: Optimizing Efficiency in Automotive Component Production. Automotive Technology Review, 33(2), 145-160.

4. Garcia, M. et al. (2022). Material Considerations in CNC Machining for Automotive Applications. Materials Science and Engineering: A, 832, 142357.

5. Wilson, D. (2018). Cost-Benefit Analysis of Multi-Axis CNC Machining in Automotive Prototyping. International Journal of Advanced Manufacturing Technology, 95(5-8), 1875-1889.

6. Thompson, E. & Davis, L. (2023). Advancements in CNC Technology for Sustainable Automotive Manufacturing. Sustainable Production and Consumption, 35, 523-537.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.