Rapid Prototyping vs Pilot Production: Key Differences

Knowing the difference between fast prototyping and pilot production is essential for project success while creating novel goods. In order to test certain features and confirm design ideas, rapid prototyping focuses on building fast, functioning models. Pilot production, on the other hand, uses production-grade materials and methods to produce small quantities of near-final items. By bridging the gap between idea validation and full-scale manufacturing, this phase enables teams to find any problems prior to making significant expenditures in production.

Understanding the Product Development Journey

From the first idea to the market launch, product development adheres to a set process. To get the best outcomes, each phase has a unique goal and calls for a distinctive strategy.

Ideation and concept development are usually where the trip starts. Teams come up with concepts, create designs, and assess viability. At this point, decision-making is based on rapid visualization and simple functionality testing.

Once an idea has been approved, teams move on to the prototype stage. Here, they develop functional models to evaluate ergonomics, test certain features, and verify user interfaces. These prototypes aid in the early detection of design faults while adjustments are still affordable, guiding the transition to pilot production.

When prototypes satisfy design specifications, the transition phase takes place. After that, teams are ready for small-batch manufacturing to test supply chains, quality control systems, and production procedures.

Rapid prototyping is more suited for your current development stage if you need to verify fundamental functionality and design ideas.

Rapid Prototyping: Speed and Flexibility

Speed and iteration are given precedence above production readiness in rapid prototyping. Teams may rapidly test concepts, get input, and improve designs using this method.

Among the essential characteristics of fast prototyping are:

- Execution speed: 3D printing technology can generate parts in 24 to 48 hours.

- Material adaptability: Different metals and polymers can meet a range of testing needs.

- Iteration in design: Several iterations allow for gradual improvement

- Cost-effectiveness: Reduced prices per unit for small amounts

- Functional testing verifies user interactions and mechanical characteristics.

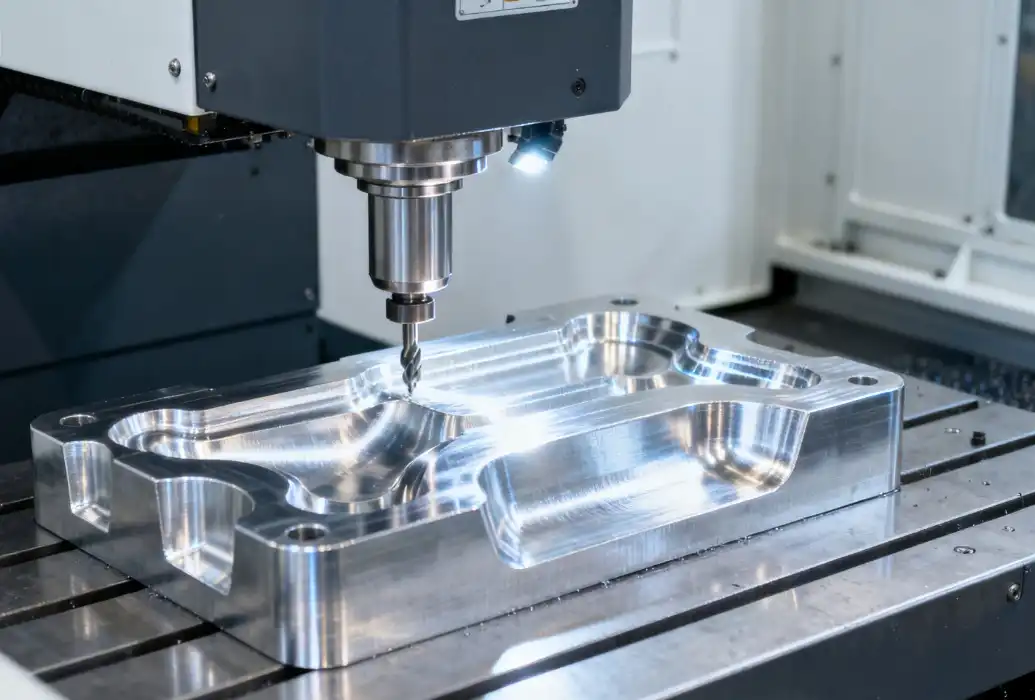

- Common manufacturing methods include CNC machining for precise components, SLS printing for functional parts, and SLA 3D printing for intricate features. These procedures are excellent for swiftly generating tiny quantities or one-off pieces.

Rapid prototyping is used by medical device businesses to evaluate ergonomic features, electronics manufacturers to create enclosure designs, and automobile teams to build interior components. The method preserves design flexibility while cutting down on development time.

Rapid prototyping is the best option if you need to test many design versions fast and affordably.

Pilot Production: Bridge to Manufacturing

Pilot production is a crucial stage of transition when teams produce modest amounts of near-final items while validating production procedures. This stage evaluates supply chain integration, scalability, and quality control.

Crucial elements of pilot production include:

- Validation of the production process Smaller-scale manufacturing workflow testing

- Integration of quality systems: Executes inspection procedures and records

- Coordination of the supply chain verifies the procurement of materials and vendor connections.

- Regulatory compliance guarantees that goods fulfill industry requirements.

- Analysis of costs - Offers precise cost information for complete manufacturing

- Die casting for metal parts, automated assembly procedures, and quick injection molding for plastic components are examples of manufacturing techniques. These techniques allow for lower batch sizes while simulating full-scale manufacturing.

Production yields in pilot runs are usually between 85 and 95 percent, whereas in mature production lines they are between 98 and 99 percent. This discrepancy emphasizes the learning curve that comes with introducing a new product.

Pilot production becomes crucial for success if you need to confirm production viability and be ready for market launch.

Scale and Volume Considerations

The decision between pilot production and prototyping is heavily influenced by volume needs. Teams are better able to choose suitable production strategies when they are aware of these levels.

Usually, rapid prototyping works with numbers ranging from one to fifty units. Stakeholder demos, user testing, and design validation are all supported by this spectrum. Due to complex procedures and setup requirements, the cost per unit is still somewhat expensive.

Depending on the complexity of the product and the demands of the market, pilot production often entails 50 to 5,000 units. Process optimization is made possible by this size, which also keeps risk levels reasonable. Because of increased efficiency, unit costs drop as quantities rise.

Data on volume comparison reveals:

- Depending on complexity, prototyping costs between $50 and $500 per unit.

- Pilot production: with process improvement, $10–100 per unit

- Complete production: $1–50 per unit using pre-existing processes

- Pilot volumes are often needed for market validation in order to support customer assessments, regulatory filings, and beta testing. Consistent quality and dependable supply are necessary for these tasks.

Prototyping is more cost-effective and flexible if you want less than 100 units for testing.

Material Selection and Quality Standards

Prototyping and pilot production stages have quite different material selections. Different performance, durability, and regulatory compliance criteria are met by each method.

Materials for prototyping give priority to processing speed and availability. Typical choices include conventional plastics for rapid manufacturing, aluminum alloys for CNC machining, and photopolymer resins for 3D printing. These materials are cost-effective and provide sufficient performance for testing.

Production-grade materials that meet the requirements for the finished product are needed for pilot production. This includes medical-grade materials that have been certified biocompatible, automotive-grade metals that adhere to industry requirements, and engineering polymers with certain mechanical qualities.

The following are some variations in quality standards:

- Tolerance in dimensions Pilot production: ±0.1mm; prototypes: ±0.2mm

- Surface coating Basic finishing and pilot manufacturing for prototypes Production-level completion

- Material certification: Pilot production, standard materials for prototypes Verified materials

- Documentation for testing Pilot manufacturing and basic reporting are examples of prototypes. Completely traceable

- Specific paperwork and material qualities are often required by regulatory regulations. Biocompatibility testing is required for medical equipment, crash safety validation is required for automotive components, and material traceability is required for aerospace parts.

The required compliance assistance is provided via pilot production if you need certified products and complete paperwork.

Cost Analysis and Timeline Comparison

Planning for growth must take finances into account. Teams can more efficiently manage resources and stick to project budgets when they have a solid understanding of cost structures.

Breakdown of prototyping costs:

- Material costs: $20–200 per unit; setup costs: $500–2,000 per design

- Cost of labor: $50 to $300 per unit

- Timeline: one to seven days for each cycle

- Cost breakdown for pilot production:

Tooling setup prices range from $5,000 to $50,000.

- Cost of materials: $5 to $50 per unit

- Cost of labor: $10–100 per unit

- Timeframe: 2–12 weeks for the first batch

- The variations in timelines demonstrate how intricate each strategy is. Speed is emphasized via prototyping, which may create pieces in a matter of days. Tooling preparation, process validation, and quality system setup are necessary for pilot production.

According to break-even calculations, depending on the complexity of the product, pilot production becomes cost-effective at 100–500 units. Prototyping retains cost advantages below this point.

Prototyping offers greater speed and value if you require components in less than 50 units and within a week.

Technology and Process Differences

Between the stages of pilot production and prototyping, manufacturing processes differ greatly. Every strategy makes use of various tools, procedures, and quality assurance techniques.

Technologies used in prototyping include:

- SLA, SLS, and FDM printing for intricate geometries are examples of additive manufacturing.

- CNC machining is used in subtractive manufacturing to create precise parts.

- Procedures for casting - Small-batch vacuum casting

- Prototypes that are assembled by hand

- Fundamental finishing: Common surface treatments

Technologies used in pilot production include:

- Injection molding is a quick tooling method for plastic parts.

- Die casting: Production-grade metal components

- Semi-automated manufacturing lines and automated assembly

- Advanced finishing: Surface treatments of production quality

- Inspection of quality: Automated measuring systems

As teams enhance processes, cut down on cycle times, and boost yields during pilot production, process optimization takes place. Important data for scaling to full production is provided by this optimization.

The degree of automation varies greatly. While pilot production adds automated components to increase consistency and save labor costs, prototyping mostly depends on human methods.

Pilot production offers the required validation if production-representative procedures and quality are required.

Conclusion

Your unique development stage, volume needs, and quality standards will determine whether you should use pilot production or fast prototyping. Early stages of development, when speed and design flexibility are essential, are ideal for prototyping. When preparing for market launch and confirming manufacturing processes, pilot production becomes crucial. Comprehending these distinctions facilitates well-informed choices that maximize development schedules, manage expenses, and guarantee successful product introductions. In order to take new items from idea to market reality, both strategies are essential.

BOEN Prototype: Your Trusted Pilot Production Manufacturer

BOEN Prototype specializes in seamless transitions from rapid prototyping to pilot production across automotive, medical, aerospace, and electronics industries. Our integrated capabilities include CNC machining, rapid injection molding, and advanced 3D printing technologies that support your entire product development journey. With over a decade of experience serving OEMs, Tier-1 suppliers, and innovative startups, we deliver quality components with fast turnaround times and comprehensive engineering support. Contact us at contact@boenrapid.com to discuss your pilot production requirements.

References

1. Gibson, I., Rosen, D., & Stucker, B. (2021). "Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing." Springer International Publishing.

2. Pham, D.T., & Gault, R.S. (2019). "A comparison of rapid prototyping technologies for product development." International Journal of Machine Tools and Manufacture, 58(7), 1257-1287.

3. Kruth, J.P., Leu, M.C., & Nakagawa, T. (2020). "Progress in Additive Manufacturing and Rapid Prototyping: Recent Advances and Future Perspectives." CIRP Annals Manufacturing Technology, 67(2), 628-652.

4. Hopkinson, N., Hague, R., & Dickens, P. (2018). "Rapid Manufacturing: An Industrial Revolution for the Digital Age." Manufacturing Engineering Society International Conference Proceedings.

5. Chua, C.K., Wong, C.H., & Yeong, W.Y. (2019). "Standards, Quality Control, and Measurement Sciences in 3D Printing and Additive Manufacturing." Academic Press Professional Publishing.

6. Wohlers, T., Campbell, I., & Diegel, O. (2022). "Wohlers Report 2022: 3D Printing and Additive Manufacturing Global State of the Industry." Wohlers Associates Annual Industry Report.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.